Wood Carton Crusher Sinlge Shaft Plastic Lumps Film Bottles Woven Bag Shredder

Package size per unit product 182.00cm * 131.00cm * 173.00cm Gross weight per unit product 2000.000kg WLV SERIESSINGLE S;

Basic Info

| Model NO. | WLV600 |

| Object | Plastic Film/Rubber Lumps/Wood/Drums/etc |

| Drive | Electric |

| Principle | Screen |

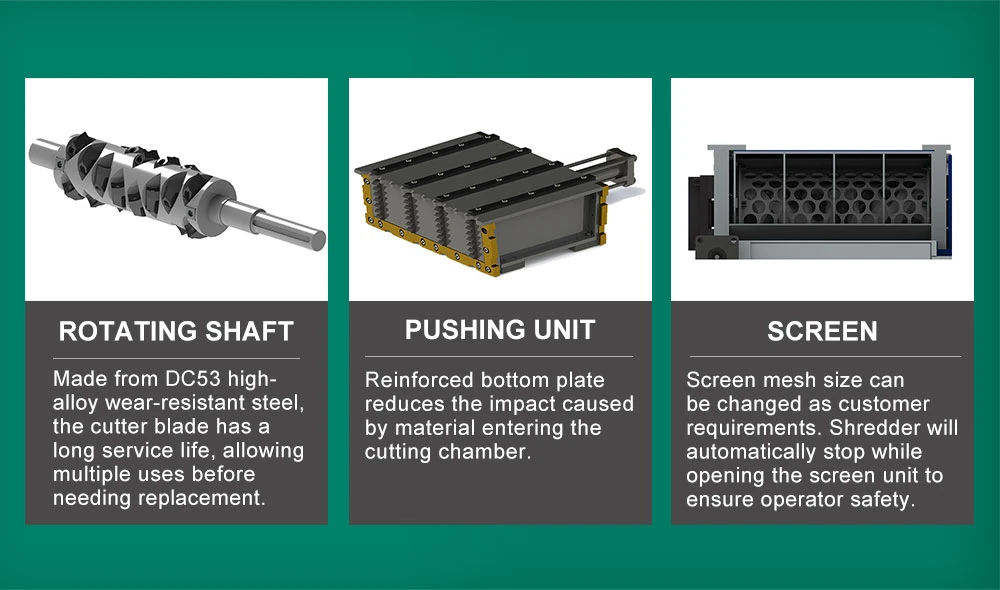

| Cutter Material | Alloy Steel DC53 |

| Motor Power | 18.5kw |

| Capacity | 300kg/H-5000kg/H |

| Screen Mesh Size | 25-40mm/Customized |

| Rotor Blade Size | 40*40mm/Adjustable |

| Knife Roll | Solid Knife Roll |

| Automation | Automatic |

| Computerized | Computerized |

| Machine Weight | About 1750kg |

| Control System | Siemens |

| Advantage | Long Service Life |

| Transport Package | Film with Wood Pallet |

| Specification | 1820*1310*1730mm |

| Trademark | WALI |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 260sets/Year |

Packaging & Delivery

Package size per unit product 182.00cm * 131.00cm * 173.00cm Gross weight per unit product 2000.000kgProduct Description

| Model | Power(kW) | Shredding Width(mm) | Rotation Diameter(mm) | Rotation Speed(rpm) | Machine Diameter(LWH)(mm) |

| WLV-600 | 18.5 | 600 | 220 | 80 | 1820*1310*1730 |

| WLV-800 | 37 | 800 | 400 | 80 | 2800*1800*2090 |

| WLV-1000 | 45 | 1000 | 400 | 80 | 2800*1980*2090 |

| WLV-1200 | 55 | 1200 | 400 | 80 | 2800*2500*2140 |

| WLV-1500 | 75 | 1500 | 400 | 80 | 2800*2750*2140 |

WLV series single shaft shredder is a medium-to-low-speed, large-torque crushing equipment with a wide range of applications.The crushed materials can be sold as raw materials or processed by other equipment to produce other products.According to the type of crushed material, the production capacity of this series of single shaft shredders is between 300kg/h-5000kg/h.

A:We are a manufacturer with our own factory in Ma'anshan, Anhui Province, China. Welcome to take a visit!Q:How to choose a shredder machine?

A:Our technical consulting services can help, recommend the most suitable machine and program according to your needs, capacity, site and other actual situation

Q:How about the service?

A:We provide after-sales service, including on-site installation, commissioning equipment, guidance and training of operators etc. Make regular return visits to solve your equipment problems and optimize your equipment maintenance methods

Q:How long is your delivery time?

A:Generally, it will be about 20-35 working days after deposit, which also will affected by the actual situation of the project

Q:Which trade terms is available?

A:FOB, CFR,CIF, EXW and other terms based on your needs.

You may also like

Send inquiry

Send now