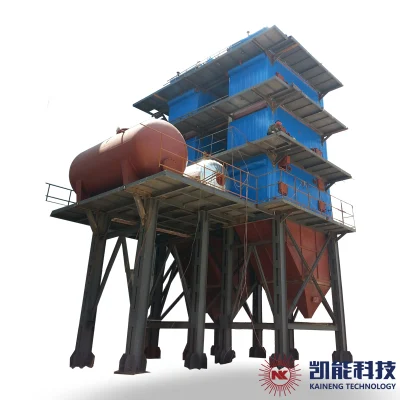

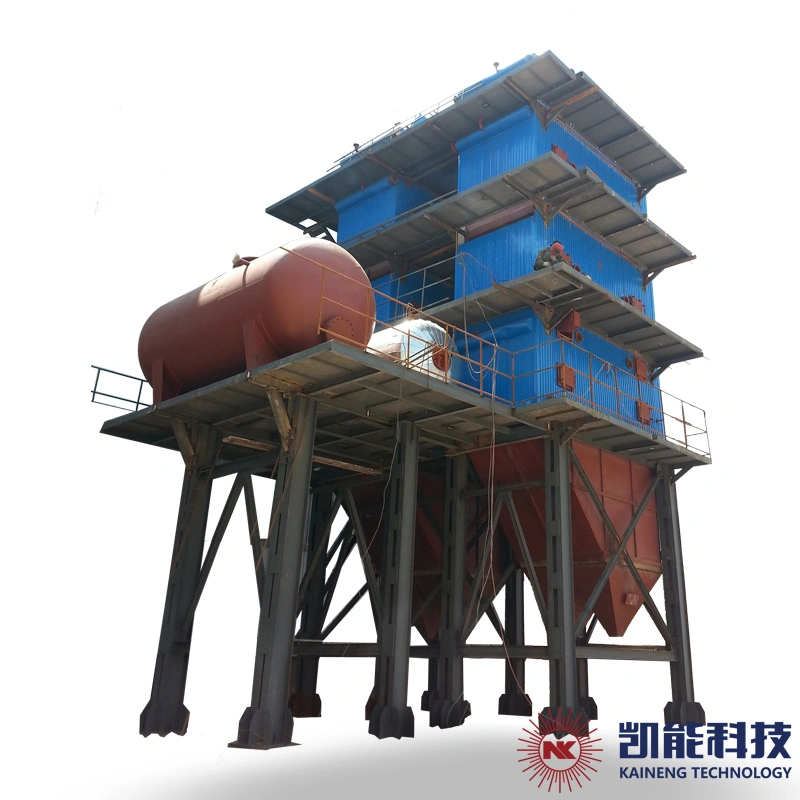

Modular Design Exhaust Gas Heat Recovery Boiler System for Kiln Furnaces

Modular Design Exhaust Gas Heat Recovery Boiler System For Kiln Furnaces Description of Heat Recovery Boiler System: the;

Basic Info

| Model NO. | KNFT-05 |

| Drum Placement | Vertical Boiler |

| Pressure | Low Pressure |

| Manufacturing Level | Class a |

| Burning Style | Waste Heat |

| Usage | Industrial, Power Station |

| Brand | Kaineng |

| Certification | ISO 9001 |

| Price | Cheap |

| Material | Carbon Steel |

| Transport Package | Wood Case or Iron Frame |

| Specification | SGS, BV, GL, LR |

| Trademark | kaineng |

| Origin | Qingdao, China |

| Production Capacity | 100PCS |

Product Description

Modular Design Exhaust Gas Heat Recovery Boiler System For Kiln FurnacesDescription of Heat Recovery Boiler System:

the boiler is modular structure.every boiler has five section: inlet exhasust gas case,superheated section,evaporator section,economizer section and outlet exhaust gas case.these sections can be transported seperately and be assembled in the spot.

Features of of Vertical Heat Recovery Boiler System:

The boiler is composed of superheated section,evaporator section,economizer and the attachments.the boiler transfer the exhaust gas heat to make 1.0MPa-2.5MPa steam.

the heat-transfer surface is composed of superheated section,evaporator section and economizer.these sections can raise water temperature,increase the steam output of the boiler and raise the effective utilization.

Advantage of Exhaust Gas Heat Recovery Boiler System:

1, high cost performance ratio

2, self-clean

3, stand wear and tear

4, low energy consumption

5, well sealed

6, small weight and size

Waste Heat Boiler parameter (for reference only, customization Available):

| S.N | Item | Description |

| 1 | Exhaust gas flow | 157000Nm3/h |

| 2 | Exhaust gas inlet | 280ºC |

| 3 | Steam capacity | 8.5t/h |

| 4 | Operating pressure (MPa) | 0.8 MPa |

| 5 | Design pressure (MPa) | 0.9 MPa |

| 6 | Rated steam temperature | 175.4ºC |

| 7 | Exhaust gas outlet | 160ºC |

| 8 | Pressure drop | <1200Pa |

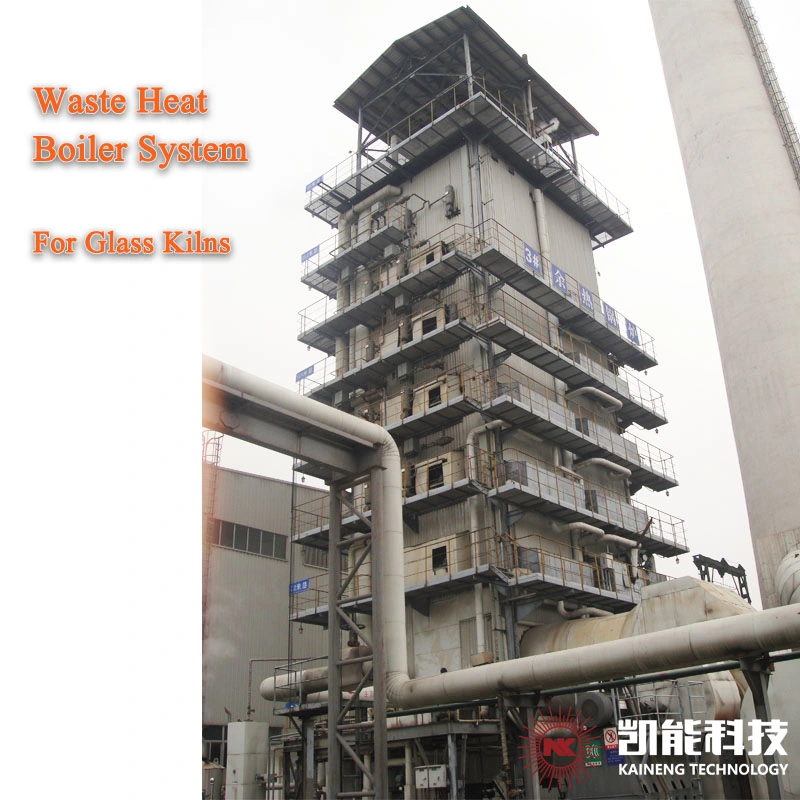

More Waste Heat Recovery Boiler Project Cases

Benefits of Waste Heat Boiler for Kiln Furnaces:

1. Highly reliable in operation and robust in construction.

2. Quick Payback Returns are achieved.

3. One time investment with lifetime returns.

4. No combustion, No emission hence Eco-friendly.

5. Energy being put to use, which was getting wasted anyway.

Kaineng Service:

Pre-sale service:

Kaineng helps customer to choose the proper waste heat recovery boiler model according to different requirements of various industry. Before delivery we will provide boiler drawings, auxiliary equipment drawings, foundation drawing, layout drawing, etc.

In-sale service:

Kaineng keeps 24 hours online and keeps close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

1. provide full range of original quality spare parts.

2. Kaineng offer project guidance service, we will dispatch engineers to your local project site to guide the installation and commissioning.

3. Our engineers will held a training for boiler workers to ensure the safe operation.

4. Free maintenance and repair for one year and lifelong service.

Kaineng Factory Area

You may also like

Send inquiry

Send now